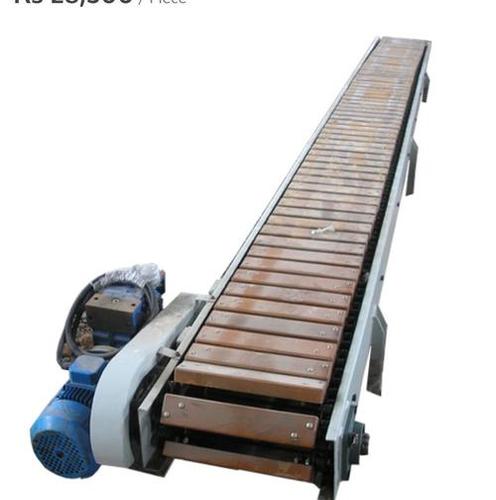

Screw Conveyor

Product Details:

- Material Mild Steel

- Type Vibrating Conveyor

- Structure Chain

- Load Capacity 200 Metric Ton

- Power 23 HP/18 kW Watt (w)

- Warranty 1 Year

- Click to View more

Screw Conveyor Price And Quantity

- 140000.00 INR/Unit

- 1 Unit

Screw Conveyor Product Specifications

- Chain

- Mild Steel

- Vibrating Conveyor

- 1 Year

- 23 HP/18 kW Watt (w)

- 200 Metric Ton

Screw Conveyor Trade Information

- 1 Unit Per Week

- 1 Week

- All India

Product Description

Screw Conveyor is ideal to convey the material constantly with ease using rotating helical screw blade. It is developed for handling and transferring coal, powders, cement, crushed material, chemicals etc. The edge of the leading side of the helix is available with a hard face welding to make it suitable for handling abrasive materials. In addition, it can also cool and handle material with very high temperature. It is designed from high-grade carbon steel or stainless steel according to the operating conditions. Highly-durable intermediate hanger bearings are available to ensure to maintain permissible sag in the rotating member.

Features of Screw Conveyor:

- Proper choice of angular speed to avoid any kind of wobbling effect during operation

- Designed using mild and stainless steel material

- Dust sealed having oil seals or 'O' rings

- Hard facing and structure on carrying side for no abrasion

Technical Specifications:

- Type : Horizontal

- Material : Carbon Steel

- Weight : Approx 500 kg

- Capacity : 200 mt/day

- Grade : Semi Automatic

- Power Required : 23 HP/18 KW

- Product type : Conveyor

Robust Mild Steel Construction

Crafted from premium mild steel, our screw conveyor promises structural strength, corrosion resistance, and long service life. Engineered with a chain structure, it reliably transports demanding loads across diverse industrial settings while minimizing operational risk.

High Load Capacity & Efficient Operation

Designed to handle up to 200 metric tons, this vibrating conveyor is ideal for continuous processing environments. Its 23 HP/18 kW power ensures efficient and consistent material flow, maximizing productivity and reducing downtime.

Comprehensive Support in India

As a one-stop distributor, exporter, manufacturer, supplier, and trader in India, we provide seamless procurement, installation, and after-sales services. Our one-year warranty enhances your investment, supported by expert technical guidance whenever you need it.

FAQs of Screw Conveyor:

Q: How does the screw conveyor with chain structure operate?

A: The screw conveyor uses a rotating helical screw blade inside a tube, combined with a chain structure, to move bulk materials smoothly. Its vibrating action promotes consistent flow, preventing clogging and ensuring efficient material transfer.Q: What materials can be transported with this mild steel vibrating conveyor?

A: This conveyor is ideal for a wide range of bulk materials such as grains, aggregates, chemicals, coal, and similar substances that require dependable, high-capacity movement in industrial operations.Q: When is it best to use a vibrating screw conveyor over other types?

A: A vibrating screw conveyor is particularly effective when handling dry bulk materials prone to sticking or bridging, or when you require efficient feeding under varying loads and want to minimize blockages.Q: Where are these conveyors commonly installed in India?

A: They are commonly installed in manufacturing plants, mining operations, agriculture processing facilities, chemical plants, and any setup requiring reliable bulk material transportation across India.Q: What is the installation process for this conveyor system?

A: Installation involves site assessment, setting up conveyor supports, assembling the chain and screw mechanism, connecting to power (23 HP/18 kW), and performing test runs to ensure optimal performance and alignment.Q: How should the screw conveyor be maintained for best performance?

A: Regular maintenance includes checking lubrication of the chain and bearings, inspecting screw and housing for wear, ensuring vibration mechanisms function properly, and cleaning any residue. Timely servicing extends operational life.Q: What are the main benefits of using your screw conveyor system?

A: Key advantages include high load capacity, efficient processing, minimal downtime, reduced maintenance needs, and robust performance backed by a 1-year warranty. It is suited for diverse industrial applications and provides a dependable material handling solution.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Vibration Sieve Pulverizer Conveyors' category

|

NAMDHARI INDUSTRIAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese