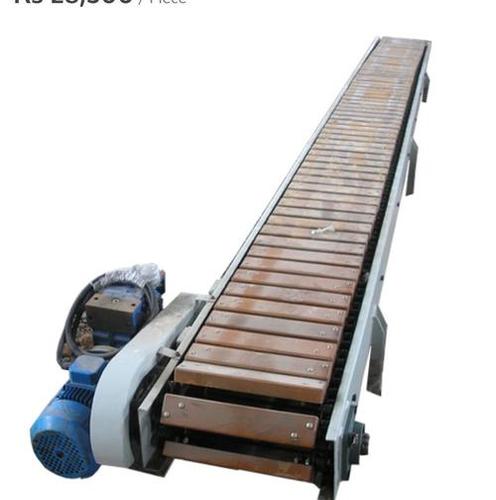

Belt Conveyor

Product Details:

- Material Mild Steel

- Type Vibrating Conveyor

- Structure Chain

- Belt Conveyor Flat Belt

- Roller Conveyor Gravity

- Vertical Conveyor Vertical Lift

- Voltage 220 Volt (v)

- Click to View more

Belt Conveyor Price And Quantity

- 140000.00 INR/Unit

- 1 Unit

Belt Conveyor Product Specifications

- 3-5 kW Watt (w)

- Flat Belt

- Gravity

- 220 Volt (v)

- Vibrating Conveyor

- Mild Steel

- 1 Year

- Chain

- Vertical Lift

Belt Conveyor Trade Information

- 1 Unit Per Week

- 1 Week

- All India

Product Description

This heavy-duty Belt Conveyor is ideal add automation and procedure fluidity in bulk handling applications. Developed from high-end conveyor belting, heavy-duty troughed idlers and structural steel frame, it is designed to handle any kind of material or job with its unique handling design. Its modern design arranges and manages the material in one constant stream. In addition to this, it is also ideal to remove the chances of spillage. Integrated skirt board provides additional handling and control. Its dual functionality design centers the material on the belt automatically and transfers it smoothly without any problem.

Features of Belt Conveyor:

- Channel frame does not require long spans

- Heavy-duty box truss frames between support points

- Exhaust ports are available for additional control

- Ideal to be used in handling coal, clinker, woodchip, bark, sand, sludge, etc.

Technical Specifications:

- Weight : Approx 500 kg

- Power Required : 23 HP/18 KW

- Grade : Automatic

- Product type : Belt Conveyor

- Conveyor material : Mild steel

- Belt material : Rubber

Robust Construction for Industrial Durability

Constructed from high-quality mild steel, the belt conveyor is designed to withstand demanding operations. Its flat-belt design and gravity roller mechanism ensure smooth movement and minimal maintenance, making it ideal for warehouses, factories, and processing plants.

Efficient Material Transport with Vertical Lift

The vertical lift feature enables seamless and safe elevation of materials between different heights, optimizing space and workflow within your facility. The vibrating conveyor mechanism further enhances consistency in material flow, reducing manual intervention.

FAQs of Belt Conveyor:

Q: How does the vertical lift feature improve conveyor operations?

A: The vertical lift enables the conveyor to transport materials between different levels, optimizing space within your facility and improving overall workflow efficiency. This is especially useful in multi-level industrial setups.Q: What materials can the flat belt conveyor handle?

A: Thanks to its durable mild steel construction and flat belt design, the conveyor is suitable for bulk materials, packages, and a variety of industrial goods. It is versatile enough for many sectors including manufacturing, warehousing, and distribution.Q: When is the vibrating conveyor type most advantageous?

A: The vibrating conveyor is particularly beneficial when a consistent flow of bulk or granular materials is needed. It helps prevent material blockages and reduces manual handling, enhancing process reliability.Q: Where can this conveyor system be installed?

A: This belt conveyor is suitable for installation in factories, warehouses, logistics centers, and other industrial environments across India. Its robust design supports a range of indoor applications.Q: What is the process for installing and commissioning the conveyor?

A: After delivery, our team or your technical staff can install the conveyor. It requires connection to a 220V power supply and proper alignment of the chain and roller structure. Testing ensures all functions, including vertical lift and vibration, operate smoothly.Q: How is the roller gravity system utilized in this conveyor?

A: The roller gravity section uses the natural force of gravity to move items along the conveyor with minimal energy input. This is cost-efficient and reduces wear on powered components.Q: What are the key benefits of using this conveyor system?

A: Key advantages include improved material handling efficiency, reduced labor costs, reliable performance in demanding settings, and the flexibility to manage various types of loads. The 1-year warranty provides added assurance of product quality and support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Vibration Sieve Pulverizer Conveyors' category

|

NAMDHARI INDUSTRIAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese