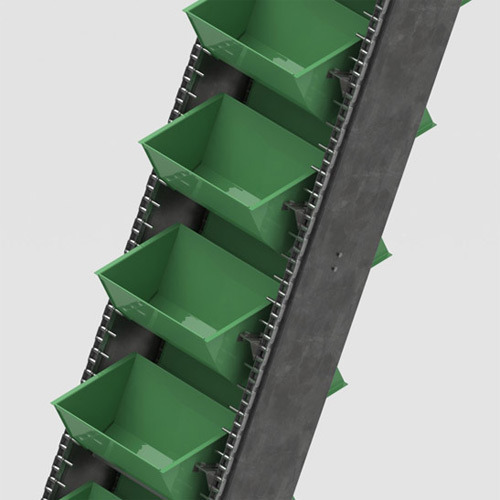

Chain Type Bucket Elevator

Product Details:

- Dimension (L*W*H) Depends on model and customization

- Frame Material Mild Steel / Stainless Steel

- Structure Chain Bucket Elevator Structure

- Bucket Volume 1-30 Liters per bucket

- Belt Size As per bucket and capacity specification

- Elevating Speed 0.5 - 1 m/s

- Rolling Speed Adjustable

- Click to View more

X

Chain Type Bucket Elevator Product Specifications

- Up to 40 meters

- Heavy-duty Chain

- Adjustable

- 0.5 - 1 m/s

- As per bucket and capacity specification

- 1-10 Tons per hour

- Customizable as per requirement

- Mild Steel, Stainless Steel

- Continuous

- Depends on size and capacity

- 220V / 380V / 415V, 3 Phase

- 1-30 Liters per bucket

- Chain Bucket Elevator Structure

- Cement, Mining, Food, Grain, Fertilizer, Chemicals Industries

- 2-15 kW

- -20C to 250C

- Mild Steel / Stainless Steel

- Depends on model and customization

Product Description

Chain Type Bucket Elevator is used to lift the materials with the help of chain and bucket. It is made up of mild steel and is automatic in functioning. This type of elevator is generally used to move cement, coal or grain. Buckets are attached at fixed or regular intervals and the chain is to move continuously to lift the materials up, scooping and conveying products. We manufacture Chain Type Bucket Elevator with extreme attention to quality, functioning of the elevator and operating system. We offer this type of elevator at very reasonable prices.

Product details

| Product type | Bucket Elevators |

| Weight | 500 kg to 1000 kg |

| Voltage | 220V |

| Power | 1-3 kW |

| Material | Mild steel |

| Material of Bucket | Stainless Steel |

| Door Style | Automatic |

Versatile Material Handling

This chain bucket elevator accommodates a variety of materials, including cement, grains, fertilizers, and chemicals. Suitable for both vertical and inclined installation, its robust design ensures smooth operation under demanding industrial conditions. The choice between centrifugal or gravity discharge modes further enhances its adaptability to different process requirements.

Customizable & Durable Design

Manufactured with polymer, mild steel, or stainless steel buckets and frame materials, this elevator is tailored to your operational needs. Customizable in size, feed inlet, bucket volume (1-30 liters), and lifting height, it ensures optimal integration. Finishes such as painted, powder coated, or galvanized surfaces provide lasting protection against corrosion and wear.

Efficient Power & Low Maintenance

Driven by a motor-gearbox system with adjustable speeds and available in various power ratings (2-15 kW), this elevator maintains consistent performance. The design includes easy inspection and maintenance sections, reducing downtime and operational costs. Its low-noise operation contributes to a better working environment, making it a preferred choice for many industries.

FAQ's of Chain Type Bucket Elevator:

Q: How does the Chain Type Bucket Elevator operate in different discharge modes?

A: The elevator can function in either centrifugal or gravity discharge modes. Centrifugal discharge efficiently propels material outward at higher speeds, while gravity discharge gently releases products for delicate or friable materials. The mode selection depends on your specific handling needs.Q: What are the benefits of using polymer, mild steel, or stainless steel buckets?

A: Polymer buckets are lightweight and corrosion-resistant, suitable for food and chemical applications. Mild steel buckets offer durability for abrasive materials, while stainless steel provides advanced resistance to corrosion and contamination, making them ideal for hygienic industries.Q: Where can the chain bucket elevator be installed?

A: It is designed for both vertical and inclined installations, allowing flexibility to match available space or processing layouts. This versatility enables its effective use in a wide range of industrial environments, including confined or multi-level facilities.Q: What is the process for customizing the elevator's feed inlet size and load capacity?

A: The feed inlet size and load capacity are fully customizable during manufacture. By specifying your material characteristics and process requirements, the elevator can be engineered to match your ideal throughput and integration needs.Q: How is maintenance performed on this bucket elevator?

A: Regular maintenance is made easy with designated inspection sections. Routine checks for chain tension, gearbox lubrication, and bucket integrity ensure reliable operation and minimize downtime, making upkeep straightforward even for large installations.Q: When is it best to choose a painted, powder coated, or galvanized surface finish?

A: If the application involves exposure to moisture or chemicals, galvanized or powder coated finishes provide superior protection against corrosion. Painted surfaces are suitable for less harsh environments, offering a cost-effective layer of defense.Q: What industries benefit most from this bucket elevator?

A: Cement plants, mining operations, food processing, grain handling, fertilizer production, and chemical industries benefit greatly from this equipment, due to its robust construction, clean discharge options, and customizable features tailored to demanding workflows.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bucket Elevators' category

|

NAMDHARI INDUSTRIAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese