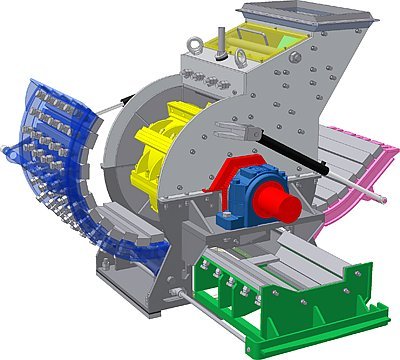

Full Circle Hammer Mill

75000 INR/Unit

Product Details:

- Product Type Full Circle Hammer

- General Use Grinding

- Weight (kg) 500 to1000 Kilograms (kg)

- Automatic Yes

- Spindle Speed 30 to 60 ft per minute mm/m

- Power 23 HP/18 KW Watt (w)

- Voltage 220 / 380 / 400 / 415 Volt (v)

- Click to View more

X

Full Circle Hammer Mill Price And Quantity

- 75000 INR/Unit

- 1 Unit

Full Circle Hammer Mill Product Specifications

- Grinding

- 220 / 380 / 400 / 415 Volt (v)

- 23 HP/18 KW Watt (w)

- 500 to1000 Kilograms (kg)

- Full Circle Hammer

- Yellow

- Yes

- 1 Year

- 30 to 60 ft per minute mm/m

Full Circle Hammer Mill Trade Information

- 1 Unit Per Week

- 1 Week

- All India

Product Description

we are leading manufacturer of Full Circle Hammer Mill screen translates to a larger screen open area and thus the highest possible production rates on materials that do not require initial grinding against a breaker plate. Suitable for gravity or pneumatic evacuation. Hammer mill fall at a the moving speed of 30 to 60 ft per minute. full screen hammer mill have 80 % screening area as compare to 50 % in half screen hammer mill.

Features:

- Efficient Grinding

- Balanced Rotor

- Gap Adjustment

- Easy Maintenance

- Lower Operational Cost

- Easy and hassle-free operation

- Sturdy design

- Easy replacement of screens and hammers

- Starts easily

- Consumes less power

- Fine quality

- Weight : 500 kg to 1000 kg

- Voltage : 220/380/400/415V

- Power Required : 23 HP/18 KW

- Grade : Automatic

- Material : Mild steel

- Product type : Hammer Mill

Efficient Grinding with Full Circle Hammer Mill

Experience superior grinding capabilities with the Full Circle Hammer Mill, built for continuous and reliable operation. It is tailored for industrial users who demand efficiency, safety, and adaptability. Whether used in manufacturing, distributing, or exporting, this mill ensures high productivity and operational flexibility, seamlessly integrating into a range of plant environments.

Advanced Automatic Features

Equipped with automatic functions, the Full Circle Hammer Mill streamlines your grinding process by reducing manual intervention. This results in uniform output and enhances operational safety. The automatic system is designed to optimize throughput while minimizing downtime, making it an ideal choice for businesses seeking consistency and high-volume processing.

FAQs of Full Circle Hammer Mill:

Q: How does the Full Circle Hammer Mill operate automatically?

A: The Full Circle Hammer Mill utilizes integrated automatic controls to manage feed rate, grinding speed, and output. This reduces the need for manual adjustments and ensures consistent performance during production.Q: What materials can be processed with the Full Circle Hammer Mill?

A: This hammer mill is designed primarily for grinding a variety of raw materials in industrial settings, including grains, biomass, and other bulk materials suitable for crushing and pulverizing.Q: When should routine maintenance be performed on the hammer mill?

A: Routine maintenance is recommended at regular intervals, typically every few months based on usage. Periodic checks ensure optimal performance and prolong the mills lifespan, all supported by a one-year warranty.Q: Where is the Full Circle Hammer Mill manufactured and distributed?

A: The hammer mill is manufactured in India and distributed globally. It is available through a network of distributors, exporters, manufacturers, suppliers, and traders.Q: What is the benefit of the automatic feature in the hammer mill?

A: The automatic feature enhances productivity and saves labor costs by streamlining the grinding process, improving consistency, and reducing the risk of operational errors.Q: How is the hammer mill installed and used safely?

A: Installation requires a stable platform and connection to the specified voltage (220, 380, 400, or 415 V). Users must follow the safety guidelines provided by the manufacturer to ensure secure and safe operation during grinding.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hammer Mills' category

|

NAMDHARI INDUSTRIAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese