Counter Flow Pellet Cooler

185000.00 INR/Unit

Product Details:

X

Counter Flow Pellet Cooler Price And Quantity

- 185000.00 INR/Unit

- 1 Unit

Counter Flow Pellet Cooler Trade Information

- 1 Unit Per Week

- 1 Week

- Asia, Australia, South America, Western Europe, Middle East, Africa, Central America, Eastern Europe, North America

- All India

Product Description

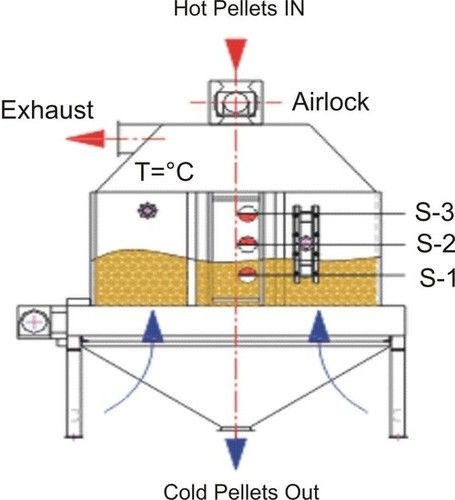

we are manufacturing of counter flow Cooler that is required to cool the feed before they are packed. It is necessary to pack the feed at required temperature and quantity. While manufacturing cattle feed, high temperature is imparted that further assists the removal of moisture by air drying process. The two required qualities can be achieved by passing the hot pellet through a cooler. This pellet cooler has the capacity to cool each corner of each pellet.

Features:

- Robust construction

- Non-corrosive

- Excellent design

- High compressive strength

- Durable

- Corrosion resistant

- Low to maintain

- Weight : 500 kg to 1000 kg

- Voltage : 220/380/400/415V

- Power Required : 23 HP/18 KW

- Material : Mild steel

- Grade : Automatic

- Product type : Pellet Cooler

Efficient Pellet Cooling Technology

Utilizing counter flow cooling principles, this Pellet Cooler rapidly reduces the temperature of processed pellets, preventing moisture buildup and preserving pellet integrity. This technology results in a uniform finish and increased product durability, meeting the demands of diverse industrial applications. The automatic operation and simple control system make daily operation seamless for production teams.

Eco-Friendly and Cost-Effective Operation

Engineered for lower energy consumption and high efficiency, the Counter Flow Pellet Cooler supports eco-friendly manufacturing while minimizing operational costs. Its stable operation and low noise feature create a safer and more pleasant working environment, promoting sustainability along the entire supply chain for distributors, exporters, and suppliers.

FAQs of Counter Flow Pellet Cooler:

Q: How does the Counter Flow Pellet Cooler work to cool pellets efficiently?

A: The cooler utilizes counter flow air technology, where cool air moves upward against the direction of falling pellets. This method ensures pellets are uniformly cooled, reducing their temperature and moisture content efficiently, resulting in enhanced pellet quality.Q: What are the key benefits of using this pellet cooler for industrial applications?

A: Key benefits include high performance, stable operation, lower energy consumption, simple automated control, eco-friendly design, low noise, and efficient cooling results. These features help ensure consistent product quality and reduce operational costs.Q: When is the optimal time to use the Counter Flow Pellet Cooler during production?

A: The cooler should be used immediately after pelletizing, when pellets are still hot and may contain excess moisture, to ensure rapid cooling and preservation of product quality before storage or packaging.Q: Where can this pellet cooler be installed, considering its dimensions and operation?

A: With dimensions of 1600*1270*3120 mm and a weight of 400 kg, the cooler can be installed in most industrial pellet processing facilities. It only requires an available space matching its footprint and access to a 380-volt power supply, making it suitable for widespread use across India.Q: What is the process for operating the Counter Flow Pellet Cooler?

A: Operation is fully automatic and managed via simple controls. Operators just need to ensure the cooler is properly loaded with pellets and configured for the desired cooling parameters. The system then runs autonomously, maintaining temperature and efficiency.Q: How does the cooler support environmental sustainability?

A: Designed with eco-friendly features and low energy consumption, the cooler minimizes environmental impact. Its stable operation and efficient cooling further contribute to sustainable manufacturing practices, aligning with modern industry standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pellet Coolers' category

|

NAMDHARI INDUSTRIAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese