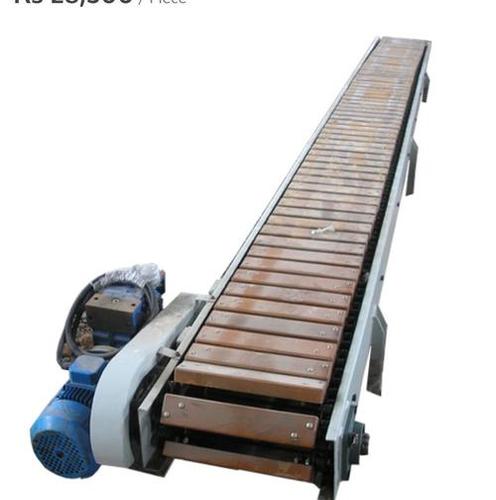

Inclined Belt Conveyor

Product Details:

- Material Mild Steel

- Type Vibrating Conveyor

- Structure Chain

- Vertical Conveyor Vertical Lift

- Load Capacity 1 to 50 Kilograms (kg)

- Power 23 HP/18 KW Watt (w)

- Warranty 1 Year

- Click to View more

Inclined Belt Conveyor Price And Quantity

- 1 Unit

- 140000.00 INR/Unit

Inclined Belt Conveyor Product Specifications

- 23 HP/18 KW Watt (w)

- Vertical Lift

- Chain

- Vibrating Conveyor

- Mild Steel

- 1 to 50 Kilograms (kg)

- 1 Year

Inclined Belt Conveyor Trade Information

- 1 Unit Per Week

- 1 Week

- All India

Product Description

Inclined Belt Conveyor is designed to bridge the level differences in the plastic injection moulding machines and varied other sectors. It is ideal to be used in applications where products are transported from one to other elevation for saving floor space. This is designed with flights or grip top belt for ensuring to safely transfer the product to the top of the incline. It comes with polyurethane profiles that are carefully welded to the underside to make the materials run within guides and the belt stay continually on track. With powder coated steel, stainless steel and aluminum material, this conveyor ensures maximum durability, sturdiness and strength.

Features of Inclined Belt Conveyor:

- Safe tracking with proper utilization of double tracking strips

- Simple, sturdy and robust construction with standard and customized widths and lengths

- Can transfer light weight mouldings to huge weight automotive parts

- Available with powerful shaft mounted motor and under slung drives

Technical Specifications:

- Grade : Automatic

- Power Required : 23 HP/18 KW

- Product type : Belt Conveyor

- Conveyor material : Mild steel

- Belt material : Rubber

- Capacity : 1 to 50kg

High Performance and Durability

Manufactured from high-grade mild steel and backed by a powerful 23 HP motor, the Inclined Belt Conveyor is built to last in demanding environments. The chain structure provides enhanced stability, while the vibrating mechanism ensures consistent, vertical movement of materials. This combination of strength and efficient design minimizes downtime and boosts productivity in your operations.

Reliable Vertical Material Handling

This conveyor model is designed specifically for vertical lifting, making it ideal for transporting materials between different floors or work levels. With a capacity up to 50 kilograms, it handles a diverse range of payloads while maintaining gentle and precise movement, ensuring materials reach their destination safely and intact every time.

FAQs of Inclined Belt Conveyor:

Q: How does the inclined belt conveyor facilitate vertical lifting?

A: The inclined belt conveyor incorporates a chain structure and a vibrating mechanism that work together to move materials vertically. This allows for efficient transfer of items to higher or lower levels within a facility, optimizing workflow and saving space.Q: What materials and capacities is this conveyor designed to handle?

A: Constructed from mild steel for strength and durability, the conveyor is engineered to transport loads ranging from 1 to 50 kilograms. It is suitable for a variety of bulk and unit materials common in industrial applications.Q: When should I opt for a vibrating conveyor with a vertical lift?

A: A vibrating conveyor with vertical lift is best chosen when your operation requires smooth, controlled, and continuous material movement between different elevations. Its especially useful where floor space is limited or where automation and speed are essential.Q: Where is the inclined belt conveyor commonly used?

A: This conveyor is widely used in manufacturing plants, warehouses, and distribution centers across India where vertical transport of goods is essential. Its versatile design allows it to integrate seamlessly into existing production lines.Q: What is the installation and maintenance process like?

A: Installation involves securing the conveyor at the desired incline and ensuring the chain and vibrating components are aligned. Regular maintenance includes checking the chain tension, ensuring the motor operates smoothly, and inspecting all moving parts for wear, all of which are supported under the 1-year warranty.Q: How can a business benefit from using this conveyor system?

A: Using this inclined belt conveyor improves operational efficiency by automating vertical transport, reducing manual labor, and lowering the risk of material damage. The sturdy construction and reliable performance also translate into long-term cost savings and enhanced productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Vibration Sieve Pulverizer Conveyors' category

|

NAMDHARI INDUSTRIAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese