Showroom

Offered Pellet Plants are comprised of many different machines, such as hammer mill, mixers, pellet mill, and coolers. Designed to cater the pelletizing tasks, these come with a typical system provision. Offered plants undergo the processes of reception of raw materials, pretreatment, balling, in-duration and cooling. The plants can be settled at mines, close to the ports or steel plants. These are virtually pollution free, making no solid or liquid remainders.

Offered Biomass Pellet make heat and electricity by burning biomass in a boiler. Insuring saved energy and costs at the same time, these are simple to clean and hold out. Used for compressing grass, bamboo powder, plant waste, straw, rice husk etc, provided carbon-neutral products provide renewable form of energy.

Provided Cattle Feed Plants are highly compact and need little investment in civil works. The modular structure of these plants is containerized and insure convenient assembly as well as leveling of the machinery. The plants are totally automatic in their procedure, insuring uniform as well as the same proportion of the ingredients in the final concoction. Provided products safe in utilization and have alarm devices for a more convenient operation.

Offered Hammer Mills are the mills, which crush & shred the aggregates and materials into small pieces via the repeated blows of small-sized hammers. These machines have various sorts of applications including ethanol plants (grains), farm machine, milling grain, fluff pulp defiberizing, fruit juice production, grinding etc. These are capable to separate the small particles from the larger ones.

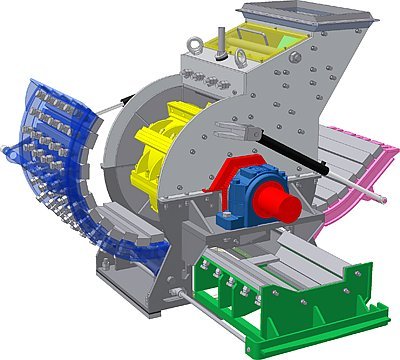

Pellet Mills are the products, which come with the principle of straightforward. These are essentially the steel drums, incorporating vertical or horizontal drums or rotating shafts. The materials are impacted by the hammer bars and are thereby expelled or shredded via screens in the drum of a chosen size. Offered mills can be employed as the primary, secondary and tertiary crushers.

We offer Auto Bagging Machines, which have been designed to enhance the productivity as well as to trim down the cost from semi to automated packaging applications such as automotive, electronics, pharmaceutical, food, crafts, plumbing, cosmetics, hardware etc. Requiring minimal maintenance, these come with improved output and accuracy. Proffered with automatic programmable devices, these have high performance for filling open mouth bags, valve mouth bags, sacks etc.

Provided Mixer Machines come with an efficient mixing eloquence. Featured with troughs and agitators, these specially designed machines are based on the construction that offers a triple mixing action insuring fast & expeditious blending. The configuration and dimensions of these products are cautiously balanced so as to provide a motion of material within the container and to avoid dead spots.

We offer Pellet Coolers, which work through a dynamic process involving concurrent heat as well as mass transportation between the cooling air and the pellets. The cooling system of these products meet different requirements. These coolers are designed to efficaciously cool a range of products by withdrawing enough moisture and heat for further storage or handling of the pellets.

We deal in Crumbler Machines, which have optimal output power, input voltage, voltage range, oscillation frequency, input current, functional efficiency, duty cycle and several others. Depicting easy technical designs, these are effortless to install. Having low energy consumption, these Pellet Crumbler Machine are particularly designed for breaking up the pellets in small particles.

Particularly in the alimentary and beverage, drugs, and chemical

sectors, sieving machines are

important. Our company prides pleasure in providing high-quality, trustworthy,

efficient, and easy to use machines.

Our cattle feed machines

are additionally highly successful because of their cutting-edge features,

which assist save time and minimizing waste. Additionally, because they are

simple to take care of and keep clean, they will last more time and keep

working at their peak for many years in the future.

We take pleasure in providing excellent pellet plants that not only meet but also surpass the expectations

of our clients. Our plants are a terrific investment for companies wishing to

boost their production capacity since they are built to be dependable and

user-friendly.

Our slat conveyors are made

of high-quality materials that can endure even the hardest working

circumstances, so they are built to last. They are perfect for industrial

applications that call for efficient and continuous material handling since

they are particularly designed to handle huge loads and enormous quantities of

goods.

The material handling sector relies heavily on screw conveyors, particularly when transporting large products from

one place to another. Our business recognizes the value of dependable

machinery, which is why we provide premium conveyors that are strong,

effective, and simple to use.

Pharmaceutical, chemical, and food processing sectors, among others,

all rely heavily on Powder Sieving

Machines. Through the removal of impurities and contaminants, they are

intended to guarantee the quality and consistency of powders.

Our Double Cone Blenders are

the go-to tools if you are searching for a dependable and effective way to mix

dry powders and grains. Our blenders are adaptable and perfect for a variety of

sectors due to their sturdy construction that can handle varied materials.

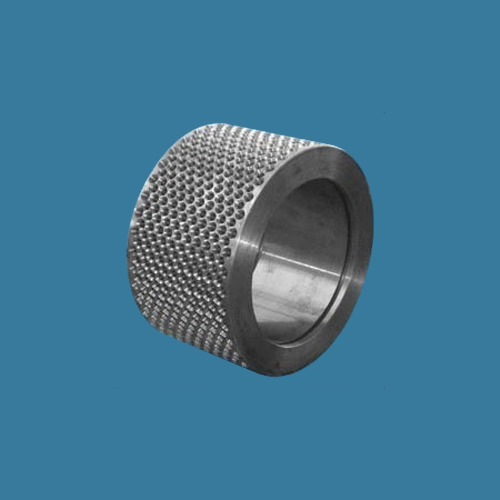

Roll shells are an essential part of heavy-duty machinery

such as crushing equipment and pellet mills. Because of this, our business

takes great satisfaction in offering products of exceptional quality that are

made to resist even the most demanding working circumstances.

In industries, impact

pulverizers are frequently used to reduce the material size. The material

is broken up by these machines using a high-speed spinning rotor, creating

small particles that may be employed for a number of tasks.

For many sectors, grinder

machines are a necessary tool for breaking down materials into smaller,

easier-to-handle quantities. Depending on the particular requirements of your

application, these machines come in a broad range of designs and setups.

|

NAMDHARI INDUSTRIAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese