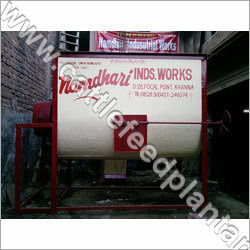

Single Shaft Paddle Mixer Machine

95000 INR/Unit

Product Details:

- Product Type Mixer Machine

- General Use Mixing

- Material Other

- Weight (kg) 500 to 1000 Kilograms (kg)

- Automatic Yes

- Voltage 220 / 380 / 400 / 415 Volt (v)

- Color Gray

- Click to View more

X

Single Shaft Paddle Mixer Machine Price And Quantity

- 95000 INR/Unit

- 1 , , Unit

Single Shaft Paddle Mixer Machine Product Specifications

- Mixer Machine

- 1 Year

- Mixing

- 500 to 1000 Kilograms (kg)

- 220 / 380 / 400 / 415 Volt (v)

- Other

- Gray

- Yes

Single Shaft Paddle Mixer Machine Trade Information

- Cash Against Delivery (CAD), Paypal, Cash in Advance (CID), Cash Advance (CA)

- 1 , , Unit Per Week

- 1 Week

- All India

Product Description

This Single Shaft Paddle Mixer Machine is available in a unique single paddle design that ensures to divide the housing into zones that is efficiently served by two paddles. This mixing machine is designed with a modern design that ensures the competent movement of particles to generate a dynamic interaction between the divided zones. In addition to this, voids are created automatically to direct the particles for arbitrarily filling the voids. These voids have high volume that ensures to attain high-speed of mixing. Accuracy can also be attained by limiting the voids size.

Features of Single Shaft Paddle Mixer Machine:

- Homogenous mixing with consistent quality

- Short mixing time without any noise, heat and vibration

- Gently mixing with no degradation and wastage

- High-production rate with low operation cost

Technical Specifications:

- Material : Mild steel

- Grade : Automatic

- Power Required : 23 HP/18 KW

- Weight : 500 kg to 1000 kg

- Voltage : 220/380/400/415V

- Product type : Mixer Machine

Efficient Mixing for Diverse Applications

Engineered for consistent results, the Single Shaft Paddle Mixer Machine is suitable for mixing powders, granules, and other materials in industries such as food, chemicals, and agriculture. Its automated operation maximizes throughput and reduces manual intervention, ensuring uniform blends every cycle.

Built for Heavy-Duty Performance

With a capacity to process between 500 and 1000 kilograms per batch, this paddle mixer delivers high productivity without compromising mixing quality. The robust construction and versatile voltage compatibilities make it adaptable for a wide range of industrial environments across India.

FAQs of Single Shaft Paddle Mixer Machine:

Q: How does the Single Shaft Paddle Mixer Machine achieve uniform mixing?

A: The mixer uses strategically placed paddles on a rotating shaft to thoroughly blend ingredients. Its automatic operation ensures consistent speed and movement, resulting in homogeneous mixtures throughout each batch.Q: What materials can be processed in this paddle mixer?

A: This mixer is suitable for powders, granules, and other solid or semi-solid materials common in food, chemical, agricultural, and pharmaceutical industries.Q: When is routine maintenance recommended for optimal performance?

A: It is advisable to perform routine maintenance checks every few months, or after every 500 hours of operation, to ensure the machine continues to run smoothly. Regular inspections help minimize wear and prolong the equipments service life.Q: Where is this mixer machine commonly supplied and exported?

A: Manufacturers, distributors, exporters, and suppliers based in India provide wide coverage, distributing the machine across local and international markets to meet various industrial needs.Q: What is the process for installing the mixer at a facility?

A: Installation involves securing the machine on a stable surface, connecting it to the appropriate voltage outlet (220/380/400/415V), and following the manufacturers instructions for assembly and safety checks before initial use.Q: How does using this paddle mixer benefit industrial operations?

A: Automated mixing reduces labor and operational costs while improving batch consistency. The machines large capacity makes it ideal for scaling up production and meeting high demand in commercial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Mixer Machines' category

|

NAMDHARI INDUSTRIAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese