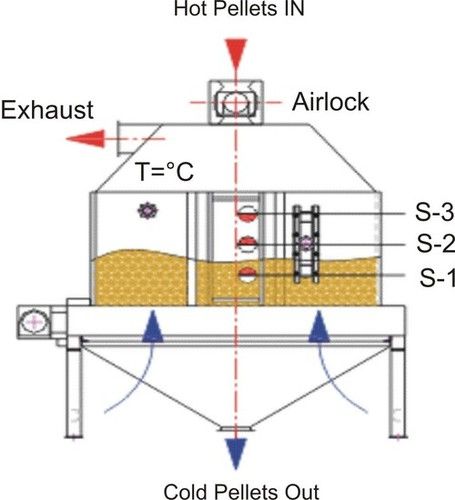

Horizontal Pellet Cooler

185000.00 INR/Unit

Product Details:

X

Horizontal Pellet Cooler Price And Quantity

- 1 Unit

- 185000.00 INR/Unit

Horizontal Pellet Cooler Trade Information

- 1 Unit Per Week

- 1 Week

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia

- All India

Product Description

We are leading manufacturer of Horizontal Pellet Cooler Cooley post- cooking and drying equipment the pellet feed in full and evently cooley with counter flow cooley principal. Unique sliding valve and discharging unit for stable running and smooth discharging. After being cooled, the pellet temperature is about 3-5 degrees higher then the room temperature . It is especially suitable for cooling for expended and extruded feed. Cooling efficiency and improve the pellet water stability and hardness. it is also convenient for transportation and storing. It is suitable for drying and all kinds of material of lump powder pellet extrude in the feed industry as well as the other industry.

Features:

Features:

- Robust construction

- Non-corrosive

- Excellent design

- Durable

- Corrosion resistant

- Low to maintain

- Weight : 500 kg to 1000 kg

- Voltage : 220/380/400/415V

- Material : Mild steel

- Product type : Pellet Cooler

- Grade : Automatic

- Power Required : 23 HP/18 KW

Superior Performance with Advanced Cooling Technology

Our Horizontal Pellet Cooler integrates innovative 3D design technology for optimal pellet cooling. Its automatic control system ensures that pellets are cooled uniformly, maintaining high efficiency while minimizing operational energy costs. The coolers eco-friendly features and stable operation make it a reliable choice for those seeking sustainable pellet processing solutions.

Eco-Friendly and Energy Saving Operation

Engineered for lower energy consumption, the cooler uses efficient mechanisms to reduce environmental impact without sacrificing performance. Its low noise output and simple controls make it accessible to operators of varying skill levels, while high efficiency optimizes production quality.

FAQs of Horizontal Pellet Cooler:

Q: How does the automatic control enhance the pellet cooling process?

A: The automatic control system promotes consistent cooling by adjusting operational parameters based on pellet load and temperature, ensuring high efficiency and minimizing human error during operation.Q: What is the process for installing the Horizontal Pellet Cooler?

A: The cooler can be installed in pellet production facilities by following the supplied manufacturers guidelines, which accommodate standard voltage inputs (220/380/400/415V) and positional requirements for its 5001000 kg weight range.Q: When is it advisable to utilize this pellet cooler during the production cycle?

A: This cooler should be used immediately after pelletizing to quickly reduce pellet temperature, which helps maintain product integrity and prepares pellets for subsequent packaging or storage.Q: Where is this horizontal pellet cooler typically used?

A: It is commonly used in industrial settings such as feed mills, biomass plants, and other pellet manufacturing facilities across India, where rapid and reliable pellet cooling is required.Q: What are the benefits of using the Horizontal Pellet Cooler with automatic features?

A: Key benefits include stable operation, high performance, simple controls for ease of use, lower energy consumption, eco-friendly operation, low noise production, and enhanced overall efficiency.Q: How does the cooler contribute to eco-friendly manufacturing?

A: By consuming less energy and ensuring high operational efficiency, the cooler reduces its environmental footprint, making it ideal for facilities prioritizing sustainable production processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pellet Coolers' category

|

NAMDHARI INDUSTRIAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese