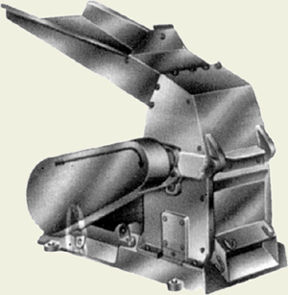

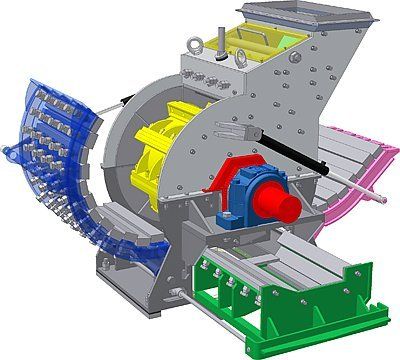

Single Door Circle Hammer Mill

75000 INR/Unit

Product Details:

- Product Type Hammer Mill

- General Use Grinding

- Weight (kg) 500 to 1000 Kilograms (kg)

- Automatic Yes

- WorkingSpeed 30 to 60 ft per minute

- Power 23 HP/18 kW Watt (w)

- Voltage 220 / 380 / 400 / 415 Volt (v)

- Click to View more

X

Single Door Circle Hammer Mill Price And Quantity

- 75000 INR/Unit

- 1 Unit

Single Door Circle Hammer Mill Product Specifications

- 500 to 1000 Kilograms (kg)

- Grinding

- Grey

- Yes

- 23 HP/18 kW Watt (w)

- Hammer Mill

- 220 / 380 / 400 / 415 Volt (v)

- 1 Year

- 30 to 60 ft per minute

Single Door Circle Hammer Mill Trade Information

- 1 Unit Per Week

- 1 Week

- All India

Product Description

We are leading manufacturer of Single Door Circle Hammer Mill. The range of hammer mill is well-known for the qualitative features of robust construction high output with low power consumption. Hammer mill fall at a the moving speed of 30 to 60 ft per minute. The hammer mill offered by us is subjected to grinding tests at our experimental station before it is delivered to the esteemed clients. Hammer mill, fall at a the moving speed of 30 to 60 ft per minute.

Features:

Features:

- Time saving

- Only requires changes of screens hammers and liners

- Economical unit

- High output with low power consumption

- Easy to operate

- Easy Maintenance

- Lower Operational Cost

- Efficient Grinding

Versatile Voltage Options

The Single Door Circle Hammer Mill supports multiple voltage settings (220, 380, 400, 415 Volt), ensuring compatibility with a wide range of electrical systems in different regions. This feature allows businesses across India and international markets to deploy the mill without concerns about electrical mismatches, enhancing convenience and reducing setup time.

Efficient Grinding Performance

Designed primarily for grinding applications, the automatic hammer mill achieves working speeds between 30 to 60 ft per minute. This efficient processing rate streamlines industrial operations, reduces manual intervention, and maintains consistent output quality. The powerful 23 HP/18 kW motor provides reliable performance for various materials.

FAQs of Single Door Circle Hammer Mill:

Q: How does the Single Door Circle Hammer Mill operate automatically?

A: The hammer mill features an automatic mechanism that controls material feeding and grinding, reducing manual handling and ensuring continuous, uniform processing. Its built-in motor and control systems enable smooth operation at varying speeds.Q: What materials can be processed with this hammer mill?

A: It is generally used for grinding agricultural items, grains, biomass, and other industrial raw materials, making it suitable for food processing, feed manufacturing, and waste reduction industries.Q: When is routine maintenance recommended for the hammer mill?

A: Routine maintenance is advised every few months or after processing large batches, with additional checks recommended under heavy-duty use. Lubrication, inspection of wear parts, and cleaning should be performed regularly to ensure peak performance.Q: Where can I purchase the Single Door Circle Hammer Mill in India?

A: You can acquire this hammer mill from authorized distributors, exporters, manufacturers, suppliers, and traders throughout India. For export options, connect with listed international dealers supplied by the manufacturer.Q: What is the installation process for this machine?

A: Installation involves placing the hammer mill on a stable foundation, connecting to the compatible voltage supply, and following the manufacturers setup instructions. Professional installation is recommended to ensure optimal performance and safety.Q: How is this hammer mill beneficial for grinding operations?

A: Its automatic function, high power, and variable speed enable fast and consistent grinding, greatly improving productivity while minimizing operational costs. The robust build and warranty further add to reliability and long-term savings.Q: What safety measures should be followed during operation?

A: Operators should ensure the machine is properly grounded, follow recommended maintenance schedules, and use protective equipment. Adhering to manufacturer guidelines will help prevent accidents and equipment damage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hammer Mills' category

|

NAMDHARI INDUSTRIAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese